The Value of Effectively Sourcing UH-60 Parts for Safe and Reliable Operations

The importance of effectively sourcing UH-60 components can not be overemphasized, as the stability and safety and security of air travel procedures rest on the high quality of these components. Making use of certified parts not only ensures conformity with extensive design criteria yet likewise reduces the risks associated with subpar options. In addition, the implications of sourcing choices expand beyond prompt operational effectiveness, influencing long-term maintenance prices and aircraft integrity. As we explore the important aspects of sourcing thoroughly, the calculated advantages and concealed difficulties may reveal insights that are important for maintaining operational quality.

Understanding UH-60 Component Specs

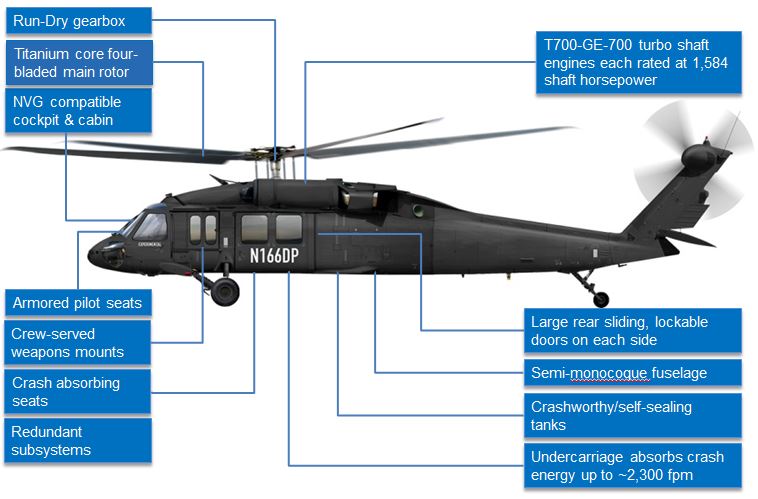

Comprehending the ins and outs of UH-60 component specifications is vital for making certain operational effectiveness and safety and security in aeronautics upkeep. The UH-60, widely utilized in army and private applications, needs parts that fulfill stringent design and regulatory requirements. Each part is thoroughly made to carry out under particular conditions, and variances in specifications can bring about efficiency failures or safety and security threats.

Element requirements incorporate various qualities, including material make-up, dimensional resistances, and functional thresholds. As an example, rotor blades should comply with exact weight and wind resistant profiles to guarantee optimum flight features. Additionally, parts need to undergo extensive screening to confirm their integrity and toughness within the requiring settings typical of aeronautics operations.

Each component might birth markings indicating conformity with armed forces or industry criteria, making sure that it has actually undergone the essential inspections and quality evaluations. Extensive understanding of component requirements is essential for upkeep personnel, enabling them to recognize authentic parts and preserve the functional stability of the UH-60 fleet.

Threats of Utilizing Substandard Components

The integrity of aeronautics operations depends upon the quality of components utilized in aircraft upkeep, particularly for the UH-60. Making use of low-grade components presents substantial dangers that can jeopardize both safety and operational effectiveness. These elements might not fulfill the extensive criteria developed for armed forces aeronautics, leading to unpredictable performance and potential system failings.

Substandard components can lead to boosted damage on critical systems, ultimately shortening the life expectancy of the airplane and demanding costly repair services or substitutes. Furthermore, using substandard products may bring about catastrophic failures throughout flight, jeopardizing the lives of crew members and passengers alike.

In addition, reliance on non-compliant parts can expose operators to regulative and legal consequences, as aircraft should abide by rigid standards stated by regulating bodies. This can result in grounding of the airplane and significant operational hold-ups.

Advantages of Certified Components

Qualified components provide a wide variety of advantages that substantially boost the security and dependability of UH-60 procedures - uh 60 parts. Among the main advantages of these elements is their adherence to rigorous top quality criteria. Qualification processes guarantee that each part has gone through strenuous screening and evaluation, thus confirming its performance and durability under numerous operational problems

The assimilation of licensed elements likewise assists in smoother maintenance treatments. Professionals can be positive in the reliability of these parts, minimizing the probability of unplanned repair work and enhancing general operational performance. The long-term cost-effectiveness of qualified parts can not be overemphasized; while they might come at a greater preliminary price, their reliability and performance equate into lower maintenance and replacement expenses over time. Eventually, spending in qualified parts is vital for the effective and risk-free operation of UH-60 airplane.

Sourcing From Reliable Vendors

When sourcing parts for UH-60 airplane, partnering with credible suppliers is crucial to making sure top quality and integrity. The safety and efficiency of military aircraft depend considerably on the stability of their elements, making it critical to choose distributors with a tested performance history in the industry. Reliable providers stick to strict top quality control procedures and frequently hold pertinent certifications, you can try here which serve as a testimony to their commitment to excellence.

In addition to high quality assurance, established vendors give thorough support solutions, consisting of technological aid, service warranty programs, and prompt shipment. This degree of engagement is vital for preserving functional preparedness and minimizing downtime. Moreover, respectable suppliers are normally a lot more clear regarding their sourcing techniques, ensuring that the parts provided fulfill rigorous regulative requirements and work with existing systems.

It is also useful to consider suppliers that focus on UH-60 components, as they have thorough expertise of the aircraft's specifications and demands. By leveraging the expertise of these distributors, drivers can improve the security and effectiveness of their operations, eventually leading to enhanced mission success. For that reason, spending time in sourcing from reliable suppliers is an essential step toward attaining optimum efficiency in UH-60 airplane procedures.

Long-Term Expense Effectiveness

Achieving long-lasting cost efficiency in sourcing UH-60 parts requires a calculated strategy that stabilizes initial investment with ongoing functional costs. Organizations needs to focus on top quality over price, as substandard components may lead to constant repair work and increased downtime, ultimately inflating general expenses. By spending in dependable, licensed components, operators can boost the airplane's efficiency and longevity, reducing the risk of unforeseen failings.

In addition, establishing long-term connections with credible suppliers can produce financial benefits, such as bulk buying discounts and favorable repayment terms. These collaborations promote accessibility to superior items and technical assistance, making sure that the sourcing procedure lines up with governing requirements and functional requirements.

Moreover, carrying out an organized stock management approach permits better projecting of component requirements, reducing excess supply and linked holding expenses. Consistently assessing supplier performance and component dependability try this site can also notify future acquiring decisions, enabling companies to adjust to evolving operational needs effectively.

Ultimately, a concentrate on lasting price efficiency in sourcing UH-60 parts not just safeguards operational integrity yet likewise adds to a much more lasting economic design, permitting reinvestment in vital aeronautics capacities.

Conclusion

In final thought, the proper sourcing of UH-60 parts is necessary for preserving risk-free and effective air travel operations. Adhering to stringent requirements and utilizing certified elements alleviates the threats connected with low quality parts.

The value of appropriately sourcing UH-60 parts can not be overemphasized, as the stability and safety and security of aviation procedures hinge on the top quality of these elements.Comprehending the intricacies of UH-60 part specs is vital for ensuring operational effectiveness and security in aviation maintenance. Extensive knowledge of component specs is vital for upkeep personnel, allowing them to determine genuine components click here for more and preserve the functional stability of the UH-60 fleet.

When sourcing components for UH-60 aircraft, partnering with respectable distributors is crucial to guaranteeing quality and dependability.Attaining long-term cost performance in sourcing UH-60 components needs a tactical technique that stabilizes preliminary financial investment with ongoing functional costs.